No spoilage, no excursion and on time: hybrid solution delivers on challenging multinational shipment

With disruptions to pharma shipments possible at any number of points along the supply chain, robust solutions are required if substantial wastage of medicines is not to occur. For temperature-sensitive goods, this concern is even greater given additional logistical challenges. That’s where hybrid solutions come into consideration.

In April 2022, a China-based pharma company was attempting to import approximately 120kg of Good Manufacturing Practices (GMP) materials for biopharma products from the USA. Existing passive cold chain container solutions would not be able to keep the shipment at the necessary temperature range of +2°C to +8°C for longer than 120 hours.

The extensive lane of New York City, USA (JFK) to Shanghai, China (PVG) via Chicago, USA (ORD), presents a number of challenges for shippers. Besides regular delays at customs, shipments to China can often experience disruption in the cold chain upon arrival at airports. Any shipment taking more than 120 hours would likely result in a temperature excursion.

A hybrid solution

Apex Logistics China worked with SkyCell to use the new 1500X hybrid container to handle the sensitive pharma shipment. SkyCell performed a lane risk assessment for Apex Logistics China which showed that the 1500X would not only provide enough runtime, but would retain approximately 60% of its energy when touching down in Shanghai.

The 270-hour runtime of the 1500X ensured that the shipment contents would be maintained at the required temperature for a sufficient period even in the case of delays at customs or in moving shipments from the airport tarmac to the cold chain storage centers. With the 1500X’s rechargeable energy system, the 270-hour runtime could also be extended indefinitely when stored in a reefer truck or cold chamber.

Fail to prepare, prepare to fail

SkyCell performs lane risk assessments in order to calculate and mitigate for possible disruptions during shipments. By using historical data and the results of real-world tests, SkyCell is able to provide customers with practical and strategic information for each lane. Assessments are powered by nearly one billion data points, providing our solutions team with a large pool of data to test and map lanes to improve safety and reliability.

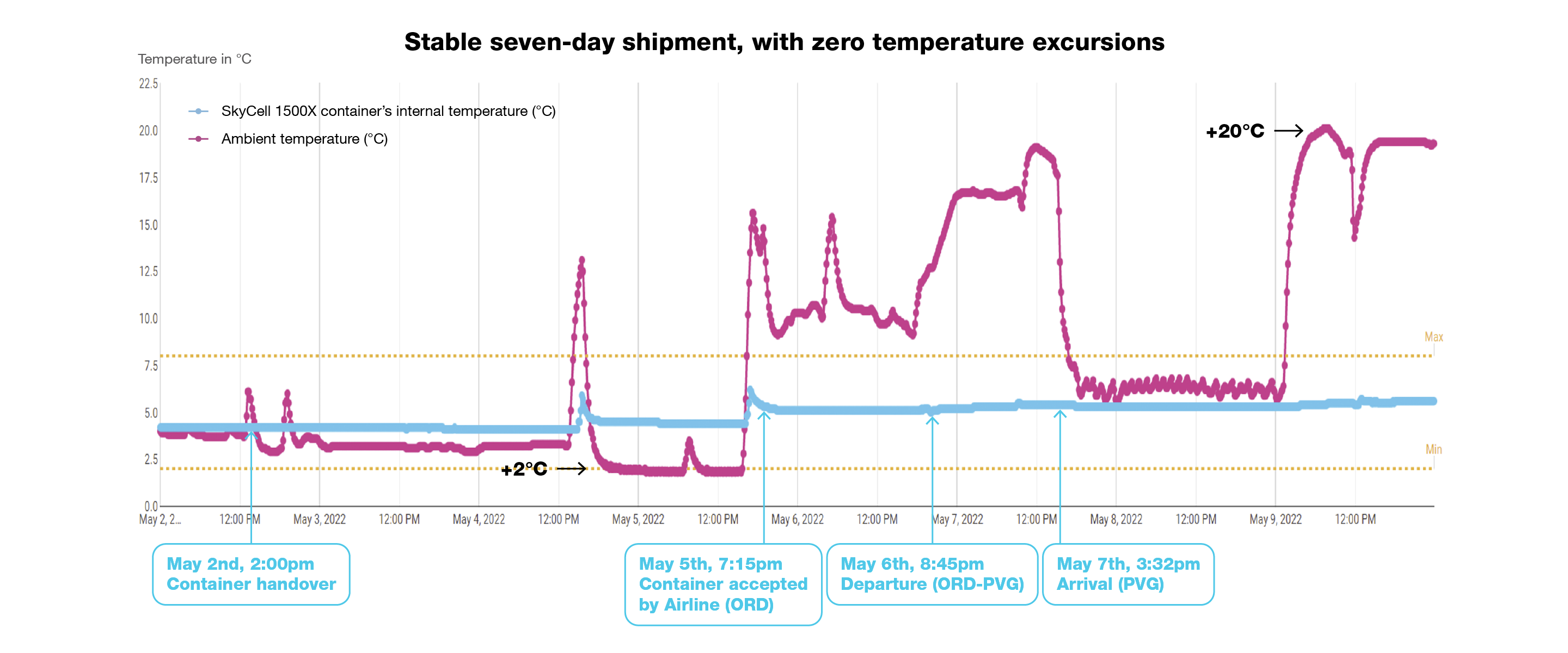

The shipment from the USA to China performed almost identically as it did during the lane risk assessment, with zero temperature deviations. The GMP materials arrived safely with more than enough energy to spare. Temperatures never exceeded the designated range over the seven-day period, this is despite external temperatures reaching between +2°C to +20 °C.

The shipment was not completely without risk. During transit, the doors of the container were opened to check the contents by customs departments on multiple occasions. Thanks to SkyCell’s combination of hardware and software, the customer has full end-to-end visibility of their shipment. Due to the cooling technology fitted in the container, the temperature remained stable. A two-day check at customs also had no impact on the shipment contents due to the 1500X’s extensive runtime of 270 hours.

A happy customer

Erin Huang, director of Airfreight for Apex Logistics China, remarked on the smooth process of working with SkyCell and using the 1500X:

“SkyCell was recommended by more than three of our customers also in the pharma industry. The results turned out to be even better than our expectations. We were able to put an entire pallet’s worth of product in the 1500X maintaining a constant temperature for more than eight days. This is a remarkable improvement on the cooler cartons we used before which featured ice gels and only offered up to four days of cooling. We are grateful to the SkyCell team for being able to guide us through using the 1500X and the smooth process for the shipment.”

With a market-leading audited temperature excursion rate of less than 0.1%, SkyCell’s technologies protect shipments and reduce in-transit failure rates to almost zero. We will continue to work hand in hand with our customers to transform the pharma supply chain.